Ezigbo ihe izizi IC ngwaahịa elektrọnik Ngwa elektrọn Ic Chip Nkwado BOM Ọrụ DS90UB953TRHBRQ1

Njirimara ngwaahịa

| Ụdị | Nkọwa |

| Otu | Sekit jikọtara ọnụ (ICs) |

| Mfr | Ngwa Texas |

| Usoro | Ụgbọ ala, AEC-Q100 |

| ngwugwu | teepu & Reel (TR) Mpempe akwụkwọ (CT) Digi-Reel® |

| SPQ | 3000T&R |

| Ọnọdụ ngwaahịa | Na-arụ ọrụ |

| Ọrụ | Serializer |

| Ọnụego data | 4.16Gbps |

| Ụdị ntinye | CSI-2, MIPI |

| Ụdị mmepụta | FPD-Link III, LVDS |

| Ọnụọgụ ntinye | 1 |

| Ọnụọgụ nke mmepụta | 1 |

| Voltaji - ọkọnọ | 1.71V ~ 1.89V |

| Okpomọkụ na-arụ ọrụ | -40°C ~ 105°C |

| Ụdị nkwụnye | Ugwu dị n'elu, Flank Wettable |

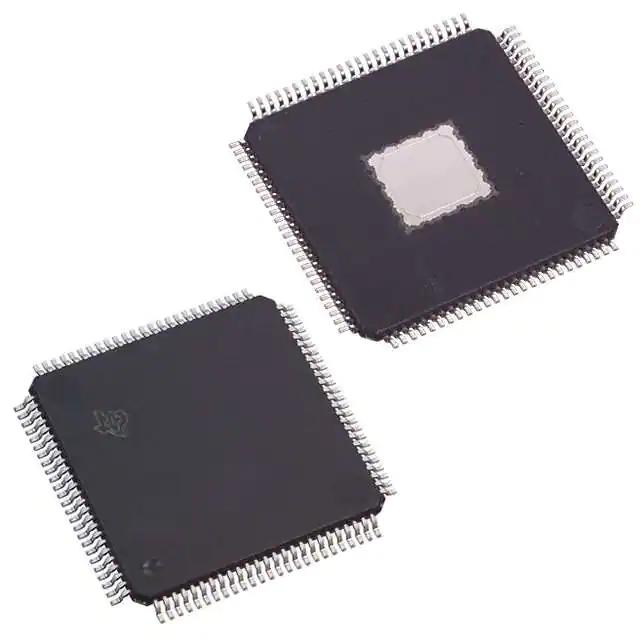

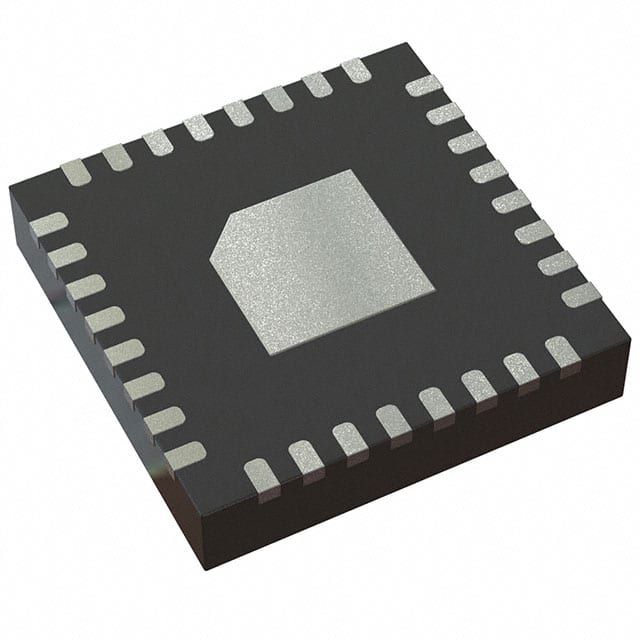

| Ngwungwu / Akpa | Mpempe akwụkwọ ekpughere 32-VFQFN |

| Ngwungwu ngwaọrụ ndị na-eweta ihe | 32-VQFN (5x5) |

| Nọmba ngwaahịa ntọala | DS90UB953 |

1.Why silicon maka ibe?Enwere ihe ndị nwere ike dochie ya n'ọdịnihu?

Ngwa ngwa maka ibe bụ wafers, nke nwere silicon.Enwere echiche na-ezighi ezi na "a nwere ike iji ájá mee ibe", mana nke a abụghị ikpe.Isi ihe mejupụtara kemịkalụ nke aja bụ silicon dioxide, na akụkụ kemịkalụ bụ isi nke iko na wafers bụkwa silicon dioxide.Otú ọ dị, ihe dị iche bụ na iko bụ polycrystalline silicon, na ájá na-ekpo ọkụ na okpomọkụ dị elu na-emepụta silicon polycrystalline.Wafers, n'aka nke ọzọ, bụ silicon monocrystalline, ma ọ bụrụ na e si na ájá mee ha, ọ dị mkpa ka a gbanwee ya site na silicon polycrystalline gaa na silicon monocrystalline.

Kedu ihe bụ silicon na ihe kpatara enwere ike iji mee ibe, anyị ga-ekpughe nke a n'isiokwu a otu otu.

Ihe mbụ anyị kwesịrị ịghọta bụ na silicon ihe abụghị ihe na-awụlikwa elu kpọmkwem na mgbawa nzọụkwụ, silicon a nụchara anụcha si quartz ájá si na elementrị silicon, silicon element proton nọmba karịa elementrị aluminum otu ọzọ, karịa mmewere phosphorus otu obere. , ọ bụghị naanị ihe ndabere ihe onwunwe nke ngwaọrụ kọmputa nke oge a kamakwa ndị na-achọ ndụ ndị ọzọ bụ otu n'ime ihe ndị nwere ike ime.Ọtụtụ mgbe, mgbe a na-asachapụ silicon ma nụchaa (99.999%), enwere ike imepụta ya na wafer silicon, nke a na-akpụzi ya na wafers.The thinner na wafer, ala na-eri nke n'ichepụta mgbawa, ma elu ihe a chọrọ maka mgbawa usoro.

Nzọụkwụ atọ dị mkpa na ịtụgharị silicon ka ọ bụrụ wafers

Kpọmkwem, mgbanwe nke silicon ka ọ bụrụ wafers nwere ike kewaa ụzọ atọ: nchacha silicon na ịdị ọcha, uto silicon kristal na-akpụ akpụ.

N'okike, a na-ahụkarị silicon n'ụdị silicate ma ọ bụ silicon dioxide na ájá na gravel.A na-etinye akụrụngwa n'ime ọkụ ọkụ ọkụ eletrik na 2000 Celsius C na ọnụnọ nke ikuku carbon, a na-eji okpomọkụ dị elu mee ihe na silicon dioxide na carbon (SiO2 + 2C = Si + 2CO) iji nweta silicon ọkwa ọkwa metallurgical (SiO2 + 2C = Si + 2CO). ịdị ọcha gburugburu 98%).Otú ọ dị, ịdị ọcha a ezughị ezu maka nkwadebe nke ngwa eletriki, n'ihi ya, a ghaghị imeziwanye ya.A na-eji silicon chloride gaseous chloride na-eme ka silicon chloride na-egweri egwepịa iji mepụta silane mmiri mmiri, nke a na-agbaze ma na-ebelata kemịkalụ site na usoro na-emepụta polysilicon dị ọcha na ịdị ọcha nke 99.9999999999% dị ka silicon ọkwa eletrọnịkị.

Yabụ kedu ka ị ga-esi nweta silicon monocrystalline si silicon polycrystalline?Usoro a na-ahụkarị bụ usoro ịdọrọ ya kpọmkwem, ebe a na-etinye polysilicon na quartz crucible ma na-ekpo ọkụ na okpomọkụ nke 1400 ° C na-ejide n'akụkụ ya, nke na-emepụta polysilicon gbazee.N'ezie, nke a na-ebute ụzọ site n'itinye mkpụrụ kristal n'ime ya na inwe mkpanaka ịse na-ebu kristal mkpụrụ ahụ n'akụkụ nke ọzọ ma jiri nwayọọ nwayọọ na-adọkpụ ya elu site na silicon gbazee.Polycrystalline silicon na-agbaze na-arapara na ala nke kristal mkpụrụ ahụ wee na-eto elu na ntụziaka nke mkpụrụ osisi kristal, nke mgbe a kpụpụtara ya ma mee ka ọ dị jụụ na-etolite n'ime otu kristal kristal nwere otu ntụgharị uche dị ka mkpụrụ kristal dị n'ime.N'ikpeazụ, a na-akụtu wafer nke otu kristal, na-egbutu, na-akpụ ya, chamfered, na-egbu maramara iji mepụta wafers niile dị mkpa.

Dabere na nha ịkpụ, enwere ike kewaa wafer silicon dị ka 6", 8”, 12, na 18”.N'ịdị ukwuu nke wafer, otú ahụ ka enwere ike ịbelata ibe n'ime wafer ọ bụla, na-ebelata ọnụ ahịa kwa mgbawa.

2.Three dị mkpa nzọụkwụ na mgbanwe nke silicon n'ime wafers

Kpọmkwem, mgbanwe nke silicon ka ọ bụrụ wafers nwere ike kewaa ụzọ atọ: nchacha silicon na ịdị ọcha, uto silicon kristal na-akpụ akpụ.

N'okike, a na-ahụkarị silicon n'ụdị silicate ma ọ bụ silicon dioxide na ájá na gravel.A na-etinye akụrụngwa n'ime ọkụ ọkụ eletrik na 2000 Celsius C na ọnụnọ nke ikuku carbon, a na-eji okpomọkụ dị elu mee ihe na silicon dioxide na carbon (SiO2 + 2C = Si + 2CO) iji nweta silicon ọkwa ọkwa metallurgical (SiO2 + 2C = Si + 2CO). ịdị ọcha ihe dịka 98%).Otú ọ dị, ịdị ọcha a ezughị ezu maka nkwadebe nke ngwa eletriki, n'ihi ya, a ghaghị imeziwanye ya.A na-eji silicon chloride gaseous chloride na-eme ka silicon chloride na-egweri egwepịa iji mepụta silane mmiri mmiri, nke a na-agbaze ma na-ebelata kemịkalụ site na usoro nke na-emepụta polysilicon dị ọcha na ịdị ọcha nke 99.9999999999% dị ka silicon ọkwa eletrọnịkị.

Yabụ kedu ka ị ga-esi nweta silicon monocrystalline si silicon polycrystalline?Usoro a na-ahụkarị bụ usoro ịdọrọ ya kpọmkwem, ebe a na-etinye polysilicon na quartz crucible ma na-ekpo ọkụ na okpomọkụ nke 1400 ° C na-ejide n'akụkụ ya, nke na-emepụta polysilicon gbazee.N'ezie, nke a na-ebute ụzọ site n'itinye mkpụrụ kristal n'ime ya na inwe mkpanaka ịse na-ebu kristal mkpụrụ ahụ n'akụkụ nke ọzọ ma jiri nwayọọ nwayọọ na-adọkpụ ya elu site na silicon gbazee.Polycrystalline silicon na-agbaze na-arapara na ala nke kristal mkpụrụ ahụ wee na-eto elu na ntụziaka nke mkpụrụ osisi kristal, nke mgbe a kpụpụtara ya ma mee ka ọ dị jụụ na-etolite n'ime otu kristal kristal nwere otu ntụgharị uche dị ka mkpụrụ kristal dị n'ime.N'ikpeazụ, a na-akụtu wafer nke otu kristal, na-egbutu, na-akpụ ya, chamfered, na-egbu maramara iji mepụta wafers niile dị mkpa.

Dabere na nha ịkpụ, enwere ike kewaa wafer silicon dị ka 6", 8”, 12, na 18”.N'ịdị ukwuu nke wafer, otú ahụ ka enwere ike ịbelata ibe n'ime wafer ọ bụla, na-ebelata ọnụ ahịa kwa mgbawa.

Kedu ihe kpatara silicon ji bụrụ ihe kacha mma maka ịme ibe?

N'ụzọ doro anya, enwere ike iji semiconductor niile dị ka ihe mgbawa, mana isi ihe kpatara silicon ji bụrụ ihe kacha dabara adaba maka ịme ibe bụ ndị a.

1, dị ka ọkwa nke elemental nke ụwa, ka: oxygen> silicon> aluminum> iron> calcium> sodium> potassium ...... nwere ike ịhụ na silicon họọrọ nke abụọ, ọdịnaya bụ nnukwu, nke na-enye ohere mgbawa iji nweta akụrụngwa akụrụngwa na-adịghị agwụ agwụ.

2, silicon element chemical Njirimara na ihe onwunwe dị nnọọ kwụsiri ike, transistor mbụ bụ iji semiconductor ihe germanium mee, mana n'ihi na okpomọkụ karịrị 75 ℃, conductivity ga-abụ nnukwu mgbanwe, mere ka ọ bụrụ PN junction mgbe ọ gachara. leakage ugbu a nke germanium karịa silicon, yabụ nhọrọ nke silicon element dị ka ihe mgbawa dabara adaba;

3, silicon element ọcha technology bụ tozuru okè, na ọnụ ala, n'oge a ọcha nke silicon nwere ike iru 99.9999999999%.

4, ihe silicon n'onwe ya abụghị ihe na-egbu egbu na nke na-adịghị njọ, nke bụkwa otu n'ime ihe ndị dị mkpa mere e ji ahọrọ ya dị ka ihe nrụpụta maka ibe.

.png)