Ngwa eletrọnịkị IC Chips Integrated Circuits IC TPS74701QDRCRQ1 otu ntụpọ zụta.

Njirimara ngwaahịa

| Ụdị | Nkọwa |

| Otu | Sekit jikọtara ọnụ (ICs) |

| Mfr | Ngwa Texas |

| Usoro | Ụgbọ ala, AEC-Q100 |

| ngwugwu | teepu & Reel (TR) Mpempe akwụkwọ (CT) Digi-Reel® |

| Ọnọdụ ngwaahịa | Na-arụ ọrụ |

| Nhazi mmepụta | Nke dị mma |

| Ụdị mmepụta | Enwere ike idozi |

| Ọnụọgụ nke ndị nchịkwa | 1 |

| Voltaji - Ntinye (Max) | 5.5V |

| Voltaji - Mpụta (Nkeji/Edozi) | 0.8V |

| Voltaji - Mpụta (Max) | 3.6V |

| Mwepụ voltaji (Max) | 1.39V @ 500mA |

| Ugbu a - Mmepụta | 500mA |

| PSRR | 60dB ~ 30dB (1kHz ~ 300kHz) |

| Njirimara njikwa | Kwado, Ike dị mma, mmalite dị nro |

| Njirimara nchedo | N'ofe nke ugbu a, karịa okpomọkụ, obere sekit, n'okpuru mgbachi voltaji (UVLO) |

| Okpomọkụ na-arụ ọrụ | -40°C ~ 125°C |

| Ụdị nkwụnye | Ugwu elu |

| Ngwungwu / Akpa | Mpempe akwụkwọ ekpughere 10-VFDFN |

| Ngwungwu ngwaọrụ ndị na-eweta ihe | 10-VSON (3x3) |

| Nọmba ngwaahịa ntọala | TPS74701 |

Mmekọrịta dị n'etiti wafers na ibe

Nchịkọta nke wafers

Iji ghọta mmekọrịta dị n'etiti wafers na ibe, ihe na-esonụ bụ nchịkọta nke isi ihe nke ihe ọmụma wafer na mgbawa.

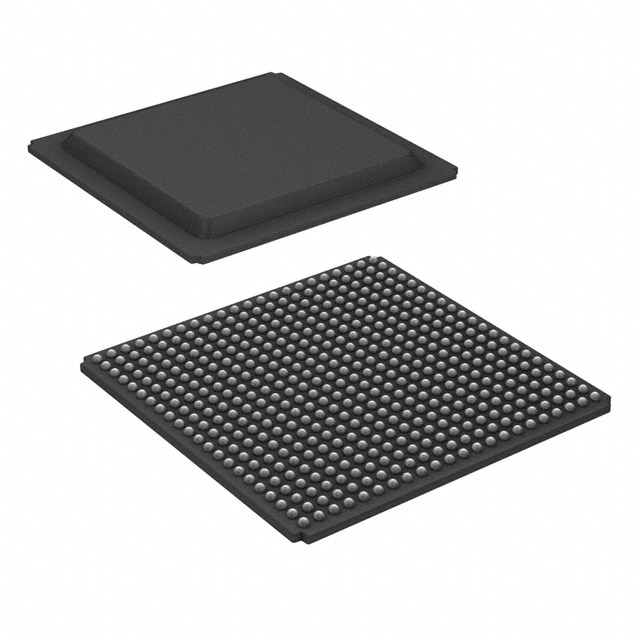

(i) Gịnị bụ wafer

Wafers bụ silicon wafers eji na mmepụta nke silicon semiconductor integrated sekit, nke a na-akpọ wafers n'ihi na ha okirikiri udi;enwere ike ịhazi ha na silicon wafers iji mepụta ihe dị iche iche nke sekit ma ghọọ ngwaahịa sekit jikọtara ọnụ na ọrụ eletrik a kapịrị ọnụ.Ngwa ngwa maka wafers bụ silicon, na e nwere silicon dioxide na-adịghị agwụ agwụ n'elu ala nke ụwa.A na-anụcha ọka silicon dioxide n'ime ọkụ arc eletrik, chlorinated na hydrochloric acid ma distilled iji mepụta polysilicon dị ọcha na ịdị ọcha nke 99.99999999999%.

(ii) Ngwa ngwa maka wafers

A na-anụcha silicon site na ájá quartz na wafers dị ọcha (99.999%) site na silicon element, nke a na-eme ka ọ bụrụ mkpanaka silicon nke na-aghọ ihe maka quartz semiconductor maka sekit jikọtara ọnụ.

(iii) Usoro nrụpụta Wafer

Wafers bụ ihe bụ isi maka imepụta ibe semiconductor.Ngwa ngwa kachasị mkpa maka sekit agbakwunyere semiconductor bụ silicon ya mere dabara na wafer silicon.

A na-ahụ silicon n'ọtụtụ ebe n'ụdị silicates ma ọ bụ silicon dioxide na nkume na gravels.Enwere ike ichikota nrụpụta nke wafer silicon n'ime usoro atọ dị mkpa: nchacha silicon na ịdị ọcha, uto silicon kristal na-etolite, na imepụta wafer.

Nke mbụ bụ nchacha silicon, ebe a na-etinye akụrụngwa nke ájá na gravel n'ime ọkụ ọkụ eletrik na okpomọkụ dị ihe dị ka 2000 Celsius C na n'ihu ikuku carbon.N'ebe okpomọkụ dị elu, carbon na silicon dioxide na ájá na gravel na-enweta mmeghachi omume kemịkalụ (carbon jikọtara ya na oxygen, na-ahapụ silicon) iji nweta silicon dị ọcha na ịdị ọcha nke ihe dịka 98%, nke a makwaara dị ka silicon grade metallurgical, nke na-adịghị. dị ọcha zuru oke maka ngwaọrụ microelectronic n'ihi na akụrụngwa eletriki nke ihe semiconductor na-enwe mmetụta nke ukwuu na ntinye nke adịghị ọcha.Ya mere, a na-emezi silicon ọkwa nke metallurgical dị ọcha: a na-edobe silicon ọkwa chlorination nke gaseous hydrogen chloride iji mepụta silane mmiri mmiri, nke a na-agbaze ma belata kemịkalụ site na usoro nke na-emepụta silicon polycrystalline dị ọcha na ịdị ọcha nke 99.99999999999999. %, nke na-aghọ silicon ọkwa eletrọnịkị.

Na-esote uto silicon monocrystalline, usoro a na-ahụkarị nke a na-akpọ ịdọrọ ozugbo (usoro CZ).Dị ka e gosiri na eserese dị n'okpuru ebe a, a na-etinye polysilicon dị elu na-adị ọcha na quartz crucible ma na-ekpo ọkụ na-aga n'ihu na onye na-ekpo ọkụ graphite gbara gburugburu n'èzí, na-ejigide okpomọkụ na ihe dịka 1400 Celsius.Igwe ọkụ dị n'ime ọkụ na-abụkarị ihe na-adịghị mma, na-ekwe ka polysilicon gbazee n'emeghị ka mmeghachi omume kemịkal na-achọghị.Iji mepụta otu kristal, a na-achịkwa nghazi nke kristal: a na-atụgharị crucible na polysilicon gbazee, a na-emikpu mkpụrụ kristal n'ime ya, a na-ebukwa mkpanaka ịse n'akụkụ nke ọzọ ka ọ na-eji nwayọọ nwayọọ na kwụ ọtọ na-adọta ya elu site na ya. silicon gbazee.Polysilicon gbazere na-arapara na ala nke mkpụrụ kristal ma na-eto elu na ntụziaka nke nhazi nhazi nke kristal mkpụrụ.