Ngwa igwe eletrọnịkị Semiconductors TPS7A5201QRGRRQ1 Ic Chips BOM ọrụ Otu ntụpọ zụta.

Njirimara ngwaahịa

| Ụdị | Nkọwa |

| Otu | Sekit jikọtara ọnụ (ICs) |

| Mfr | Ngwa Texas |

| Usoro | Ụgbọ ala, AEC-Q100 |

| ngwugwu | teepu & Reel (TR) Mpempe akwụkwọ (CT) Digi-Reel® |

| SPQ | 3000T&R |

| Ọnọdụ ngwaahịa | Na-arụ ọrụ |

| Nhazi mmepụta | Nke dị mma |

| Ụdị mmepụta | Enwere ike idozi |

| Ọnụọgụ nke ndị nchịkwa | 1 |

| Voltaji - Ntinye (Max) | 6.5V |

| Voltaji - Mpụta (Nkeji/Edozi) | 0.8V |

| Voltaji - Mpụta (Max) | 5.2V |

| Mwepụ voltaji (Max) | 0.3V @ 2A |

| Ugbu a - Mmepụta | 2A |

| PSRR | 42dB ~ 25dB (10kHz ~ 500kHz) |

| Njirimara njikwa | Kwado |

| Njirimara nchedo | N'ofe okpomoku, tụgharịa polarity |

| Okpomọkụ na-arụ ọrụ | -40°C ~ 150°C (TJ) |

| Ụdị nkwụnye | Ugwu elu |

| Ngwungwu / Akpa | Mpempe akwụkwọ ekpughere 20-VFQFN |

| Ngwungwu ngwaọrụ ndị na-eweta ihe | 20-VQFN (3.5x3.5) |

| Nọmba ngwaahịa ntọala | TPS7A5201 |

Nchịkọta nke ibe

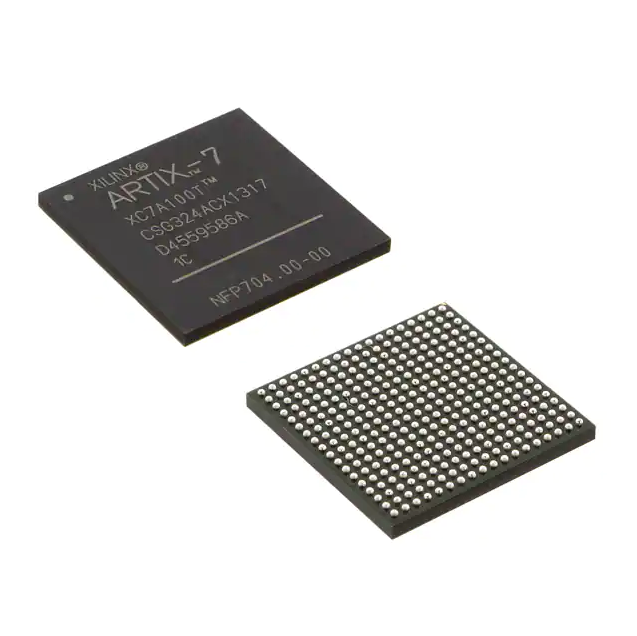

(i) Gịnị bụ mgbawa

Sekit agbakwunyere, nke akpọrọ IC;ma ọ bụ microcircuit, microchip, mgbawa bụ ụzọ nke miniaturizing sekit (tumadi semiconductor ngwaọrụ, kamakwa passive components, wdg) na ngwá electronic, na-emekarị na-emepụta n'elu nke semiconductor wafers.

(ii) Usoro nrụpụta mgbawa

Usoro nhazi mgbawa zuru oke na-agụnye imewe mgbawa, ịmepụta wafer, ngwugwu ngwugwu, na ule, n'ime nke usoro nhazi wafer dị mgbagwoju anya.

Nke mbụ bụ mgbawa imewe, dị ka imewe chọrọ, emepụtara "ụkpụrụ", akụrụngwa nke mgbawa bụ wafer.

A na-eji siliki mee wafer, nke a nụchara site na ájá quartz.Wafer bụ ihe silicon dị ọcha (99.999%), mgbe ahụ, a na-eme silicon dị ọcha ka ọ bụrụ mkpanaka silicon, nke na-aghọ ihe maka nrụpụta quartz semiconductor maka sekit agbakwunyere, nke a na-egbutu n'ime wafers maka mmepụta mgbawa.The thinner na wafer, ala na-eri nke mmepụta, ma na-achọkwu usoro.

Ihe mkpuchi wafer

Ihe mkpuchi wafer na-eguzogide oxidation na okpomọkụ na-eguzogide ma bụ ụdị fotoresisist.

Wafer fotolithography mmepe na etching

E gosipụtara usoro nhazi nke fotolithography na eserese dị n'okpuru.Nke mbụ, a na-etinye oyi akwa nke photoresist n'elu wafer (ma ọ bụ mkpụrụ) ma kpoo ya.Mgbe ihichachara, a na-ebufe wafer na igwe lithography.A na-agafe ọkụ site na nkpuchi iji wepụta ụkpụrụ dị na nkpuchi ahụ na fotoresisist n'elu wafer, na-eme ka ikpughe ma na-akpali mmeghachi omume fotochemical.A na-esizi wafers ndị ahụ ekpughere nke ugboro abụọ, nke a maara dị ka ịsa achịcha ekpughere, ebe mmeghachi omume photochemical zuru oke.N'ikpeazụ, a na-efesa onye mmepụta na fotoresist n'elu wafer iji mepụta ụkpụrụ ekpughere.Mgbe mmepe gasịrị, a na-ahapụ ụkpụrụ na nkpuchi na fotoresisist.

A na-eme gluing, ịsa achịcha, na imepe emepe na onye nrụpụta screed na ekpughere ya na fotolithograph.A na-arụkarị onye nrụpụta screed na igwe lithography inline, ebe a na-ebufe wafer n'etiti nkeji na igwe site na iji robot.A na-emechi usoro mgbasa ozi na mmepe niile na wafers adịghị ekpuchi ya ozugbo na gburugburu ebe obibi iji belata mmetụta nke ihe ndị na-emerụ ahụ na gburugburu ebe obibi na mmeghachi omume photoresist na photochemical.

Doping na adịghị ọcha

Ịkụnye ions n'ime wafer iji mepụta semiconductors nke P na N kwekọrọ.

Nnwale wafer

Mgbe usoro ndị a dị n'elu, a na-emepụta lattice nke dice na wafer.A na-enyocha njirimara eletrik nke ọ bụla nwụrụ anwụ site na iji nyocha pin.

Nkwakọ ngwaahịa

A na-edozi wafers ndị a na-emepụta, na-ejikọta ya na ntụtụ, ma mee ka ọ bụrụ ngwugwu dị iche iche dịka ihe ndị a chọrọ, nke mere na enwere ike ịkwado otu isi mgbawa ahụ n'ụzọ dị iche iche.Dịka ọmụmaatụ, DIP, QFP, PLCC, QFN, na ndị ọzọ.N'ebe a, a na-ekpebi ya site n'omume ngwa nke onye ọrụ, gburugburu ngwa, usoro ahịa, yana ihe ndị ọzọ dị n'akụkụ.

Nnwale, nkwakọ ngwaahịa

Mgbe usoro ahụ dị n'elu, mmepụta mgbawa zuru ezu.Nzọụkwụ a bụ iji nwalee mgbawa, wepụ ngwaahịa ndị nwere nkwarụ na ngwugwu ya.

Mmekọrịta dị n'etiti wafers na ibe

Ihe karịrị otu ngwaọrụ semiconductor mejupụtara mgbawa.Semiconductor bụ n'ozuzu diodes, triodes, ubi mmetụta tubes, obere ike resistors, inductor, capacitors, na na.

Ọ bụ iji teknụzụ iji gbanwee ntinye nke electrons n'efu na oghere atomịk na olulu mmiri okirikiri iji gbanwee njirimara anụ ahụ nke oghere atomic iji mepụta ụgwọ dị mma ma ọ bụ nke na-adịghị mma nke ọtụtụ (electrons) ma ọ bụ ole na ole (oghere) ka. mepụta semiconductor dị iche iche.

Silicon na germanium na-ejikarị ihe semiconductor eme ihe na akụrụngwa na ihe ha dị ngwa ngwa n'ọtụtụ buru ibu yana ọnụ ala dị ala maka iji teknụzụ ndị a.

Ihe mejupụtara wafer silicon bụ ọnụ ọgụgụ dị ukwuu nke ngwaọrụ semiconductor.Ọrụ nke semiconductor bụ, n'ezie, ịmepụta sekit dị ka achọrọ na ịdị adị na silicon wafer.